QUALITY

Quality Control System

We produce 10.000 items per month and implement inspection for all of them.

In precision instruments, quality assurance is an absolutely essential.

We introduce advanced measuring instruments and highly skilled engineers

use them in quality control section.

All of our products are supplied under the strict quality assurance standards.

In-process Product Inspection

In Production Division, all operators take responsibility for their working. Our products are checked in each phase of the processing and it helps prevent defectives.

We also compare the difference of measured values between in-process product

inspection and final inspection. It leads to improvement of inspection

and quality accuracy.

Research System

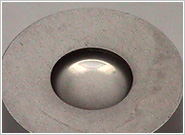

To make mold/die parts more durable, we adopt PCD (sintered diamond) for

the material of its function part. PCD is extra hard material and it requires

much more time to process. We address the challenge to finish PCD's surface

more smoothly same as other materials. Affiliated with university which

researches Polishing, we pursue the best way from diverse perspectives.

We also research the mechanism of PCD brazing with university and Industrial Technology Institute and step up efforts to strength proof and early detection of defects.

Working toward Improvements

Improvement Committee is set up for achievement of high customer satisfaction

and reduction of product defects. This committee is made up of people from

many divisions of our company and it has received over 400 suggestions

from company members since its establishment.

The suggestions are commended in monthly meeting. We provides special incentive

for particularly outstanding suggestion.

All the members of our company always make a conscious attempt to improve

each one's present situation.

banner

Nakayama Seimitsu Co.,Ltd.

Shin-Osaka Nishiura Bldg. 801,

2-7-38 Nishi-miyahara, Yodogawa-ku, Osaka

532-0004, Japan

Tel:+81(0)6-4807-1500

Fax:+81(0)6-4807-1515